A CNC router is a computerized cutting device used for large materials like wood, metal, and plastics. Computer control makes the method speedier and smoother to produce the number of identical finished goods. They have various range of operations, which boosts efficiency without wastage of much time in the production process. The significant advantage of this machine is its efficiency as multiple industries can use it for large scale productions.

One such category is 4 axis CNC router, which can swing left and right through different angles. They are most effective for 3d carving workpieces and irregular graphic processing by using geometric configuration. They are enhanced with a backup parameter, processing memory function, and can work in all processing environments. The successful production process needs accurate modeling and prototyping to achieve the next step. The CNC machine helps to craft innovative products by scanning, copying, and reverse engineer. The faster production speed also allows us to take timely future decision making.

In this article, we will study applications of CNC router to make your business more efficient or click here for CNC machining service.

Signage

If you are a complex planning a project on 2D or 3 D, this CNC machine can get the job done quickly for you. It is capable of skillfully carrying operation on materials like foam, wood, brass, and aluminum. The computerized part act as a vision of the system to maintain accuracy and efficiency within it. The modern signage shops demands of ADA compliant which works intelligently to produce

Whether you’re creating a small-scale 2D project or a more complex 3D signage component, a CNC machine can get the job done quickly and cleanly. CNC routers are capable of skillfully working with a wide range of materials, including foam, wood, plastic, acrylic, aluminum, brass, and more tactile text, braille, character spacing more.

Cabinets and furniture

This is one of the standard applications where CNC machines are used for creating standardized pieces. They include closet, doors, countertops, and chairs much more with précised efficiency. These designs are produced while giving a smooth finishing touch at the time of production. These machines minimize not only the time but also material handling through its high efficient efficiency.

Aluminum and brass machining

Working with materials like aluminum and brass requires little more attention and cutting capability. But if done accurately, it can save a lot more time and expenditure while delivering excellent results. One should know the proper utilization of spindle RPM as it works little differently with these materials.

Musical instruments

The CNC is also efficient in creating musical instruments by cutting it into exact specifications. The proper interaction of it would produce a beautiful range of sounds by helping those manufacturers producing high qualities and large quantities without compromising in the performance.

Metal Removal Industries

CNC machines play a significant role in metal removal, including the automotive, aerospace, and jewelry-making industries. This technology helps in extracting the raw materials from the end product and also provides shape to those. One can attain desired shapes, including rounded, rectangular, square, or even three-dimensional products.

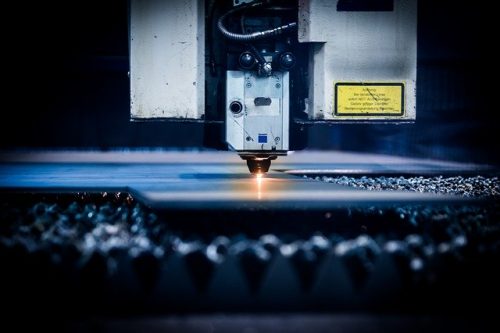

Industries for Fabricating Metals

CNC machines are required in industries that need metal or steel plates for creating their end product. Some of such well-known equipment which have been achieved easily through CNC materials include drilling precision holes, flame or plasma cutting, welding, and shearing. Some other metal industries have also been benefited from CNC machines like electronics. Electronics include lots of tiny parts, starting from computers to motherboards. The other such one is firearms, which require the CNC machine to produce barrels, ammunition clips, pins, triggers, and several components of the gun.

Conclusion

So above were some essential applications for the uses of CNC machines. They are being used in major industries to make the work much more comfortable while cutting the overall expense. Apart from these, they also have a role to play in food and beverage, woodworking, and other industries, but you need to choose the right type of CNC machine used for those applications. The list doesn’t end here; these machines are also efficient in industries like arts and crafts to produce mirrors or frames. They can make delicate architectural designs by giving them a unique touch.